Laboratory Mill 3100

The LM 3100 is designed for grinding samples of grains, pellets, meals, feeds, and forages.The ground sample can then be used for analyses such as NIR, Falling Number, Glutomatic, Kjeldahl etc. The Laboratory Mill 3100 is a hammer type cyclone mill,built into a soundproof casing.An adjustable vacuum feed control regulates the feed rate of the sample into a metallic grinding chamber. A hardened steel hammer rotates at high speed forcing the sample

through a stainless sieve. Standard sieve of 0.8 mm is used for Falling Number, Glutomatic System and NIR analyses. Sieves from 0.5 - 2.0 mm are available. The fine, homogeneous sample is separated from air in a cyclone and collected in a quick release stainless steel container. The cyclone principle makes the mill virtually self-cleaning thus increasing lab throughput, accuracy, and efficiency.

Features & Benefits

Robust Metal Construction: Reliable operation and long instrument life. Reduced Dust: Cyclone outlet with filter bag to minimize dust.

Sound Proof Casing: Low noise level.

Large Sample Capacity: Reduces sampling error - fulfills Falling Number requirement. Vacuum Feed Control: Airflow feeder regulates feeding and facilitates grinding of large samples.

Homogeneous Particle Size: Produces a fine, homogenous sample as required for Falling Number, NIR, and Glutomatic analysis.

High Moisture Grinding: Adjustable feed rate allows grinding of samples with up to 25 % moisture.

Self-Cleaning: Cyclone design minimizes cleaning between samples.

Safe Operation: Motor cannot start until door is closed and stops immediately when door is opened.

Mill Feeder 12V Supply: Integrated power plug for optional Mill Feeder eliminates external 12VDC transformer.

Approved for

Falling Number test: To determine the alpha-amylase activity in wheat and rye. Glutomatic/Gluten Index test: To determine wet gluten quantity and quality. NIR-Analysis: To determine protein, fat, hardness, ash and moisture after grinding.

Recommended Accessories

Mill Feeder: A motor driven rubber paddle Mill Feeder can be added to provide a consistent feed rate.This improves grinding of high moisture grain and grain with the hull remaining, e.g. barley, oats and rice.The constant feed rate also improves overall mill performance and reduces motor strain caused by overfeeding of sample.

Specifications

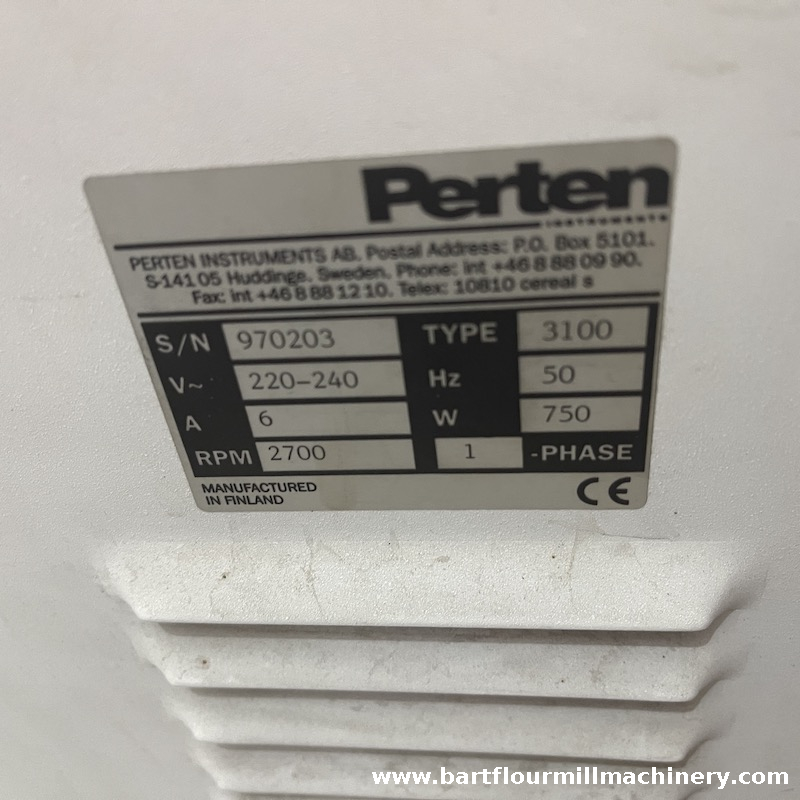

Power Requirement: 115 or 230 V, 50 or 60 Hz (specify on order) Operation: Belt drive 1:6, 16,800 rpm

Capacity: 300 g in 30-50 seconds depending on moisture content Dimensions (HxDxW): 560x510x630 mm

Net Weight: 51 kg